What is the Rubber Accelerator ZMBT?

Rubber accelerators are key chemicals used to speed up the vulcanization process of rubber, and ZMBT (Zinc 2-Mercaptobenzothiazole) is one of the most widely used accelerators in the industry. ZMBT is highly effective in enhancing the curing process, providing durability, strength, and elasticity to rubber products.

Rubber accelerators like ZMBT are vital for improving the quality and performance of rubber products across various industries, including tires, footwear, and industrial applications.

What is the chemical name of Rubber Accelerator ZMBT?

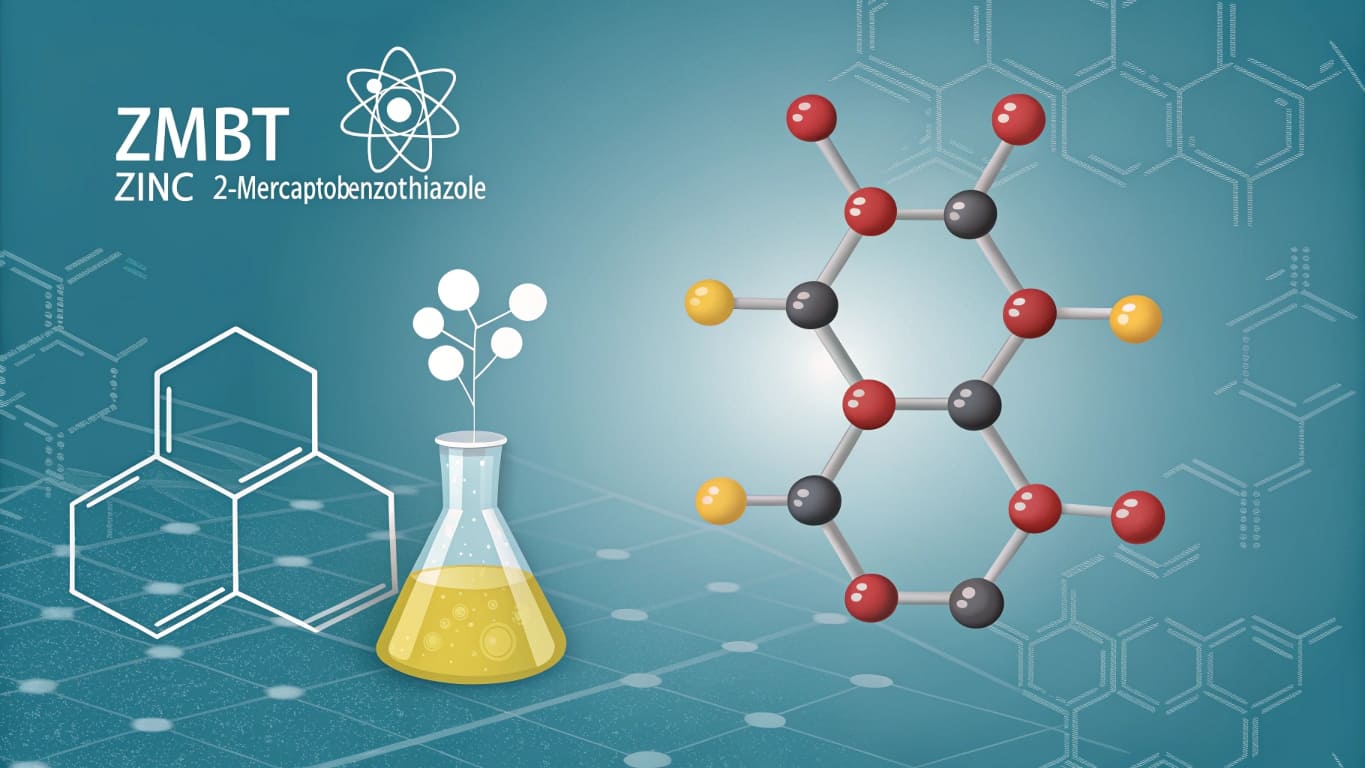

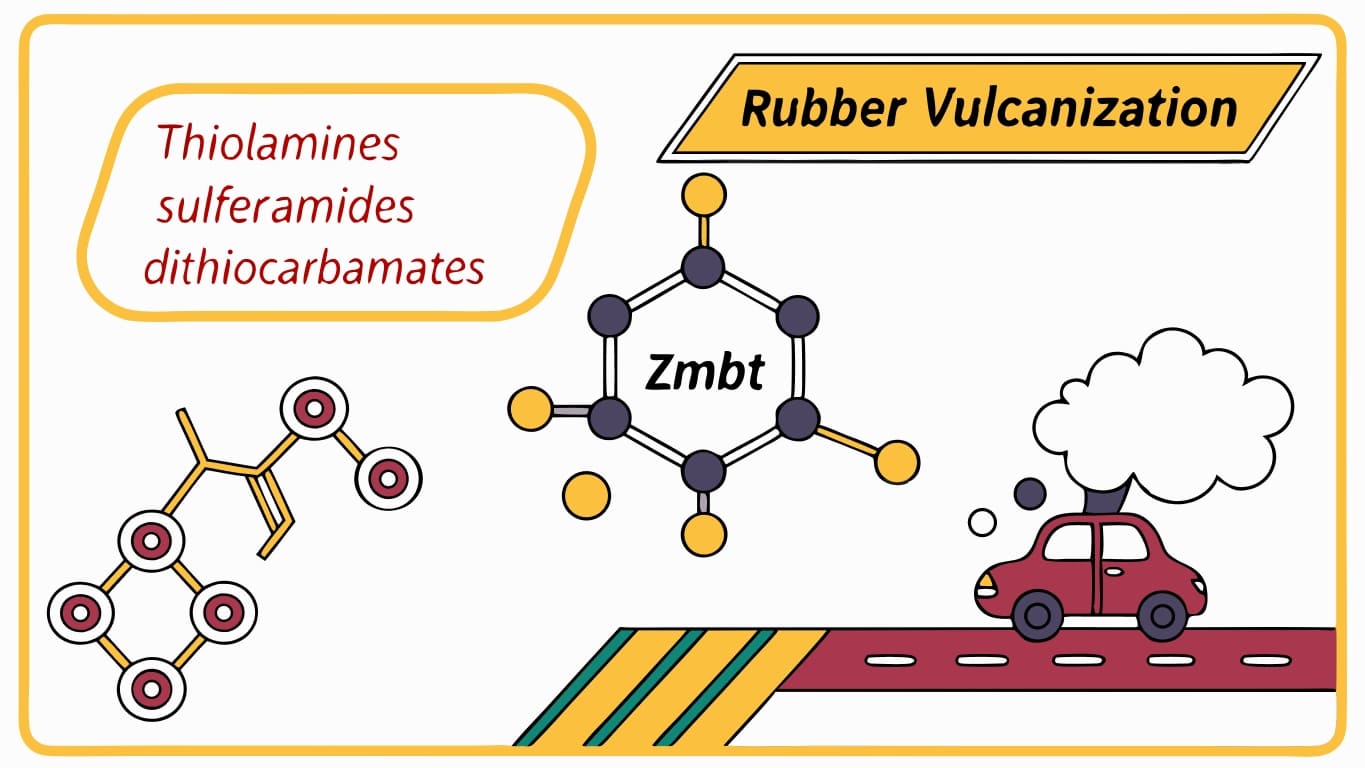

The chemical name of ZMBT is Zinc 2-Mercaptobenzothiazole. This name refers to the compound’s structure, which includes a benzothiazole ring and a mercaptan group, both of which play key roles in its ability to accelerate the vulcanization process.

ZMBT is categorized as a thiazole accelerator, commonly used in combination with sulfur to create cross-links in rubber, enhancing its strength and flexibility. Its mercaptan group makes it highly reactive, helping to promote faster curing at lower temperatures.

What is the chemical structure of Rubber Accelerator ZMBT?

ZMBT has a chemical structure consisting of a benzothiazole ring attached to a mercaptan group with a zinc atom. This structure is essential for its role in the rubber vulcanization process.

The mercaptan group (-SH) is responsible for its reactivity with sulfur during vulcanization, while the zinc atom helps in accelerating the cross-linking process. This combination results in a highly effective and efficient vulcanization agent.

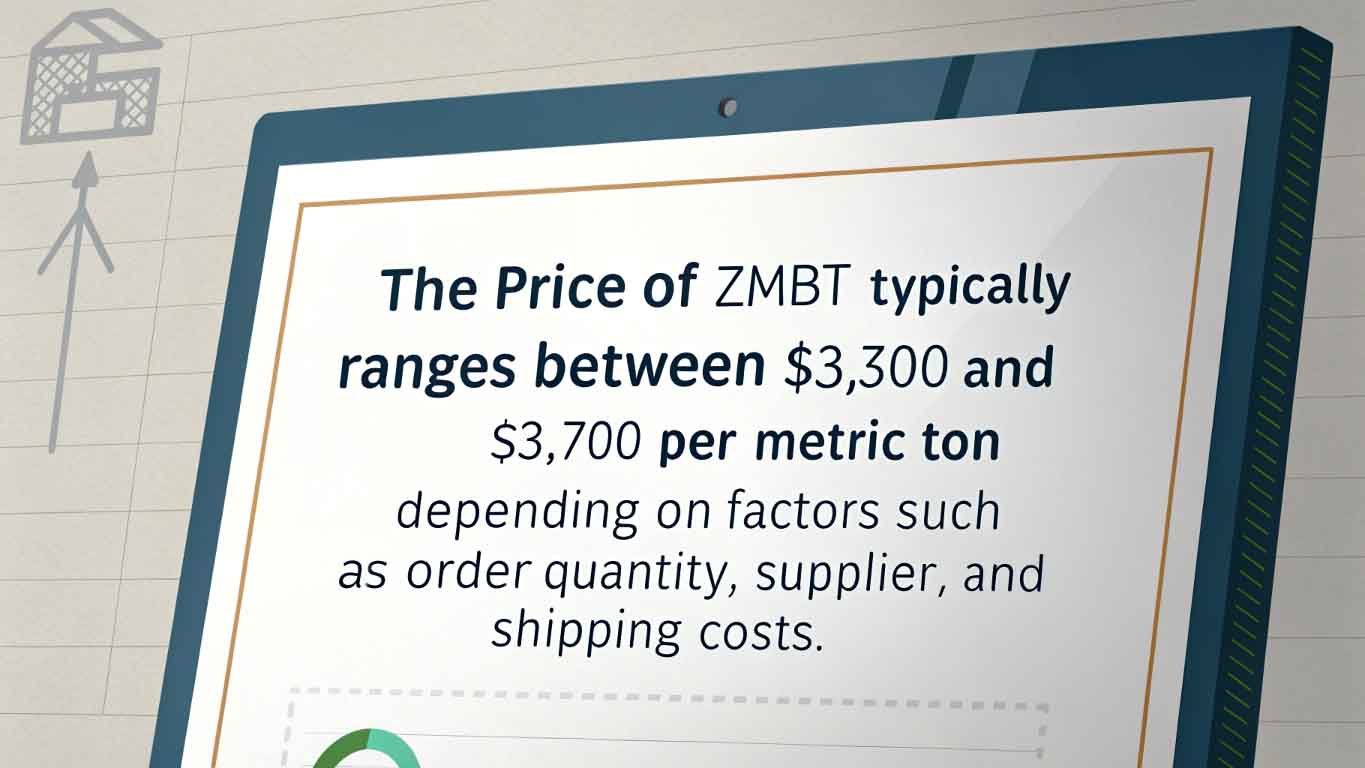

What is the price of Rubber Accelerator ZMBT?

The price of ZMBT typically ranges between $3,300 and $3,700 per metric ton, depending on factors such as order quantity, supplier, and shipping costs. Bulk orders often come with discounts, making it more cost-effective for larger manufacturers.

Pricing can vary based on the region and market conditions, and factors like freight costs or international taxes may also influence the final price. To secure the best deals, long-term contracts or bulk purchasing agreements are recommended.

What is the qualified specification of Rubber Accelerator ZMBT?

ZMBT typically meets high-quality specifications, including a purity of ≥98%, with low levels of volatile matter and ash. These standards ensure the consistency and reliability of the product when used in rubber manufacturing.

Here are the standard specifications for ZMBT:

- Appearance: Yellow powder or granules

- Purity: ≥ 98%

- Ash content: ≤ 0.5%

- Volatile matter: ≤ 0.5%

These specifications ensure that ZMBT functions effectively in a wide range of rubber products, from tires to industrial seals, while maintaining optimal performance during the vulcanization process.

What is the use of Accelerator ZMBT?

ZMBT is used as a primary accelerator in the sulfur vulcanization of rubber. It is primarily used in the production of tires, belts, and various rubber products due to its excellent performance in curing rubber quickly and efficiently.

The accelerator is particularly favored in tire manufacturing, where heat resistance and fast curing times are crucial. ZMBT also improves the elasticity, strength, and overall durability of rubber products, making it a key ingredient in many industrial rubber formulations.

What is the accelerator of vulcanization of rubber?

The main accelerators for rubber vulcanization include thiazoles, sulfenamides, and dithiocarbamates. These accelerators, including ZMBT, help speed up the cross-linking process between rubber polymers and sulfur.

Thiazole accelerators like ZMBT are particularly effective because they promote faster curing and provide better control over the vulcanization process, leading to rubber products with enhanced physical properties and greater resistance to aging.

What are Primary Accelerators?

Primary accelerators are chemical compounds used to initiate and speed up the vulcanization of rubber. ZMBT is one of the primary accelerators used in the rubber industry, known for its fast curing time and excellent scorch safety.

Other primary accelerators include MBTS and TMTD, which are often used in combination with secondary accelerators to control the rate of vulcanization. The choice of accelerator depends on the desired properties of the final rubber product, such as strength, flexibility, and heat resistance.

Conclusion

In summary, ZMBT is a highly effective rubber accelerator used primarily for the vulcanization of rubber products. It is essential in ensuring optimal performance, durability, and efficiency in various rubber applications, from tires to industrial seals.