What is Rubber Accelerator CBS?

Rubber Accelerator CBS (Cyclohexylbenzothiazole sulfonamide) is a widely used chemical in rubber manufacturing, especially in the production of high-performance rubber products. It plays a critical role in speeding up the vulcanization process, enabling manufacturers to improve production efficiency and the overall quality of rubber materials.

What is the accelerator CBS structure?

CBS is a sulfur-containing accelerator that facilitates faster vulcanization of rubber compounds, contributing to improved durability and strength.

CBS, or Cyclohexylbenzothiazole sulfonamide, has a chemical structure consisting of a benzothiazole group attached to a sulfonamide group, and a cyclohexyl ring. The presence of sulfur atoms in its molecular structure makes it effective in cross-linking the rubber molecules during the vulcanization process.

Dive deeper:

CBS's molecular structure allows it to activate sulfur atoms, which are crucial for the formation of cross-links between the rubber's polymer chains. These cross-links are what give rubber its desirable physical properties, such as elasticity, strength, and heat resistance. The structure of CBS ensures that these reactions occur at optimal speeds during the vulcanization process, which is why it is so valuable in the production of high-quality rubber products.

What is the qualified specification?

The qualified specification refers to the standards and criteria that a product must meet to be considered suitable for use in a particular application.

In the case of rubber accelerators like DPG, the qualified specifications will typically include key performance indicators such as the purity of the chemical, its effectiveness in the vulcanization process, and its compatibility with other rubber chemicals. Below is a sample table showing the typical specifications for DPG:

| Property | Specification Value |

|---|---|

| Appearance | White to Off-White Powder |

| Purity | ≥ 98% |

| Melting Point | 170 - 175°C |

| Ash Content | ≤ 0.5% |

| Solubility in Water | Insoluble |

| Specific Gravity | 1.17 - 1.20 g/cm³ |

| Volatile Matter | ≤ 0.5% |

| pH | 6.0 - 7.0 |

| Storage Temperature | 10 - 30°C |

These specifications are critical to ensuring the quality and performance of DPG in various rubber applications. It ensures that the accelerator functions effectively in the vulcanization process and that the final rubber products meet the required standards for strength, durability, and flexibility.

Dive deeper:

The specifications for CBS focus on ensuring that the accelerator delivers consistent performance in rubber curing processes. A higher assay level indicates the purity of CBS, which directly affects the efficiency of the vulcanization process. Additionally, it is important to check for any toxic substances or impurities, as these could affect the safety and end-use performance of the rubber products.

How does CBS enhance the vulcanization of rubber?

CBS accelerates the vulcanization process by promoting the cross-linking of polymer chains, resulting in stronger and more durable rubber.

CBS enhances the vulcanization of rubber by increasing the speed at which sulfur cross-links the rubber's polymer chains. This leads to a faster curing time, which is beneficial for mass production of rubber products. Moreover, CBS allows for better control over the curing process, ensuring that the final product exhibits optimal physical properties, including elasticity, tensile strength, and heat resistance.

Dive deeper:

The efficiency of CBS in vulcanization lies in its ability to facilitate the formation of sulfur bridges between polymer chains, significantly enhancing the rubber’s mechanical properties. This acceleration is critical in industries where time and consistency are paramount. As a result, CBS is favored for applications in high-demand sectors such as automotive, industrial, and medical rubber products.

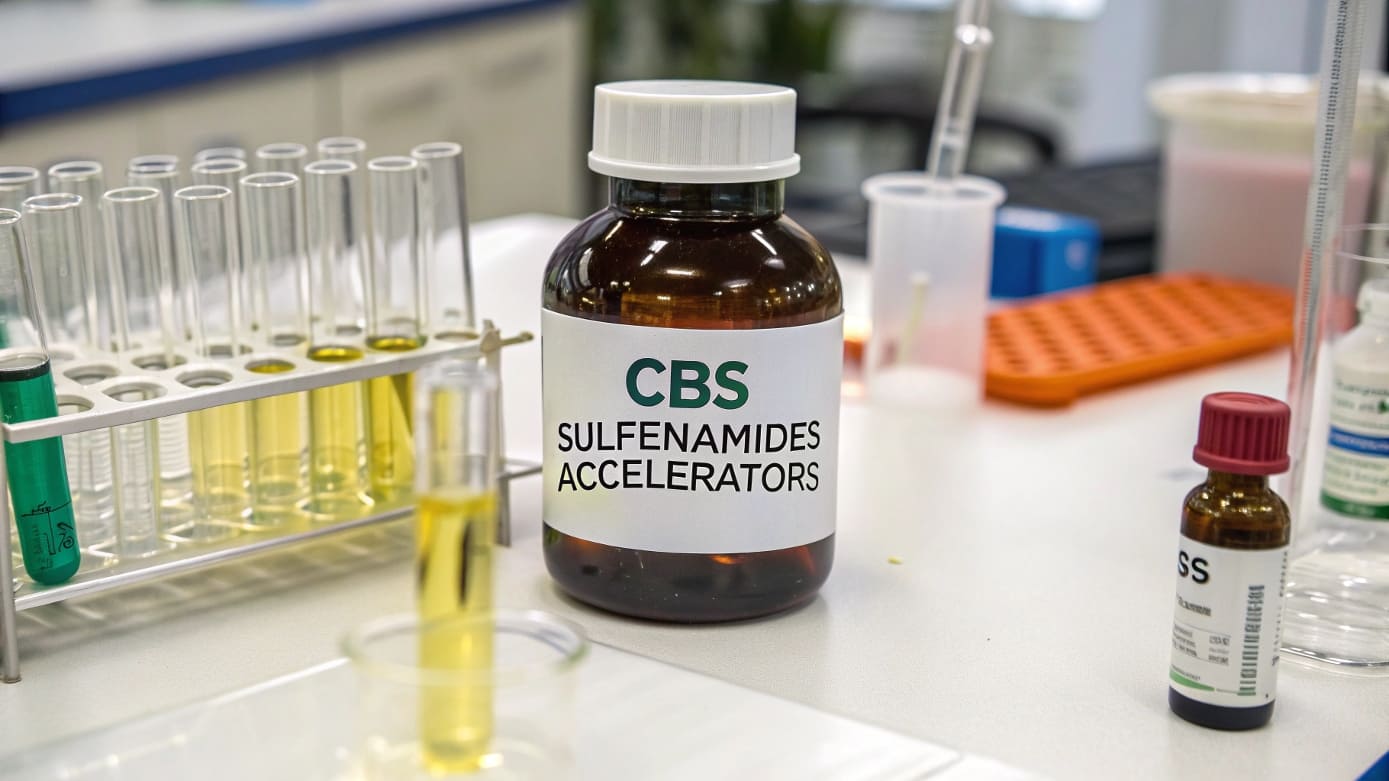

What kind of rubber accelerator CBS belongs to?

CBS belongs to the class of sulfenamides accelerators, which are highly effective in promoting sulfur vulcanization in rubber.

As a thiazole-based accelerator, CBS is part of a group of accelerators known for their ability to work at lower temperatures and with shorter vulcanization times. Thiazole accelerators, including CBS, are commonly used in the rubber industry because they are cost-effective, efficient, and can be tailored to various rubber formulations.

Dive deeper:

Thiazole accelerators like CBS work by activating sulfur, which is a key component in the vulcanization process. They are typically used in combination with other accelerators to achieve specific curing rates and properties in the rubber. CBS is preferred for its ability to balance efficiency and cost-effectiveness, making it a go-to choice in many rubber manufacturing settings.

What are the benefits and applications of CBS in rubber manufacturing?

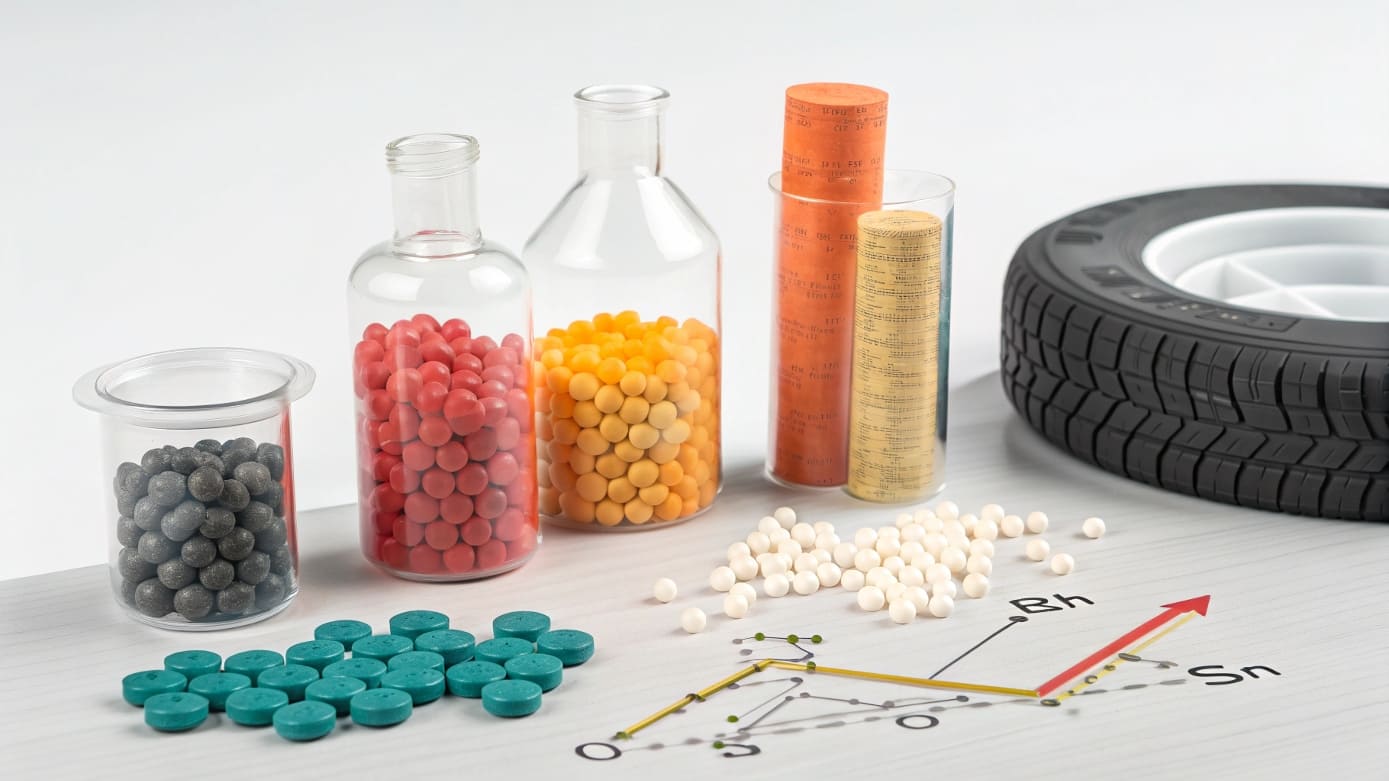

CBS provides numerous benefits, including enhanced durability, elasticity, and heat resistance, making it ideal for a variety of rubber applications.

CBS is used in the production of tires, automotive parts, footwear, and industrial rubber products, where high durability and resistance to aging and wear are essential. Its ability to accelerate the vulcanization process also improves production efficiency, making it a cost-effective solution in large-scale manufacturing.

Dive deeper:

In addition to improving physical properties such as strength and flexibility, CBS also contributes to the thermal stability of rubber, ensuring that products can withstand high temperatures without degrading. These characteristics make CBS an excellent choice for applications that require long-term performance under stress, including automotive and industrial sectors.

How does CBS affect the physical properties and aging resistance of rubber products?

CBS improves the physical properties of rubber by increasing its strength, flexibility, and aging resistance.

The use of CBS in rubber formulations results in products that have superior mechanical properties. This includes better tensile strength, tear resistance, and elongation. Additionally, CBS helps improve the aging resistance of rubber, allowing it to maintain its integrity and appearance over time, even when exposed to environmental factors such as heat, sunlight, and ozone.

Dive deeper:

The physical properties of rubber, such as elasticity and strength, are significantly enhanced by the sulfur cross-links formed during the vulcanization process. CBS's role in this reaction leads to rubber that is not only more durable but also more resistant to cracking, hardening, and other signs of aging. This is particularly important for rubber products that need to withstand long-term exposure to harsh conditions, such as automotive tires and seals.

What is the recommended dosage of CBS in different rubber formulations?

The recommended dosage of CBS varies depending on the rubber formulation and the desired vulcanization rate, typically ranging from 0.5 to 3 parts per hundred rubber (phr).

The exact dosage of CBS in rubber formulations depends on factors like the type of rubber, the desired curing speed, and the end-use properties required. In general, lower dosages are used for slower-curing formulations, while higher dosages are used when faster curing times are needed.

Dive deeper:

In rubber compounding, achieving the right balance of accelerators, including CBS, is crucial for controlling the vulcanization process. Too much CBS can lead to over-curing and reduce the rubber's flexibility, while too little may result in under-curing, which compromises the product's strength and durability. Manufacturers typically conduct tests to optimize the dosage for each specific application.

Is CBS environmentally friendly, and what safety precautions are needed during handling?

CBS is considered relatively safe for handling, but like all chemical accelerators, it requires precautions to ensure safe usage and minimize environmental impact.

CBS is not classified as a highly toxic substance, but safety precautions should be taken when handling it. It is recommended to use protective gloves, goggles, and respirators to avoid exposure to dust or fumes. Additionally, manufacturers should adhere to environmental guidelines to prevent contamination during its use and disposal.

Dive deeper:

While CBS is generally regarded as safer compared to some other accelerators, its handling still requires caution due to its potential to cause skin and eye irritation. As part of sustainable manufacturing practices, it is also important to ensure that CBS is disposed of properly to prevent any adverse environmental effects. Many companies now adopt closed systems to limit exposure and minimize waste.

Can CBS be combined with other accelerators for improved performance?

Yes, CBS can be effectively combined with other accelerators, such as zinc dithiophosphate (ZDP) or MBTS, to enhance vulcanization performance and control curing rates.

Combining CBS with other accelerators allows manufacturers to fine-tune the vulcanization process, optimizing curing times, product performance, and costs. By selecting complementary accelerators, it is possible to achieve a more balanced vulcanization, especially for complex rubber formulations.

Dive deeper:

In many cases, combining CBS with other accelerators can lead to improved performance characteristics. For example, combining CBS with ZDP can offer better heat resistance, while pairing it with MBTS can help control the curing rate more precisely. The choice of combination depends on the specific needs of the rubber product being produced, such as its intended use, durability requirements, and processing time.

Conclusion

CBS is a versatile and effective accelerator that plays a crucial role in enhancing rubber's physical properties, vulcanization speed, and aging resistance. By understanding its specifications, applications, and safety measures, manufacturers can maximize the benefits of this essential chemical in rubber production.