What is the Rubber Accelerator ZDTP?

ZDTP, or Zinc Dialkyldithiophosphate, is a specialized rubber accelerator commonly used in the rubber industry to enhance vulcanization. It significantly improves the performance and durability of rubber products.

ZDTP is an essential compound in rubber manufacturing, offering vital properties that aid in the vulcanization process. It plays a crucial role in enhancing the rubber's physical properties, ensuring the end product performs well under different conditions. Let's dive into the details of ZDTP and its various applications in rubber production.

What is the chemical name of accelerator ZDTP?

The chemical name of ZDTP is Zinc Dialkyldithiophosphate.

ZDTP is a coordination complex formed from zinc and a dialkyldithiophosphate group. The dialkyl groups in the compound often vary, which can impact its performance. This compound is primarily used for its ability to enhance vulcanization while maintaining the flexibility and durability of rubber.

Here is the parsed image information in the requested format:

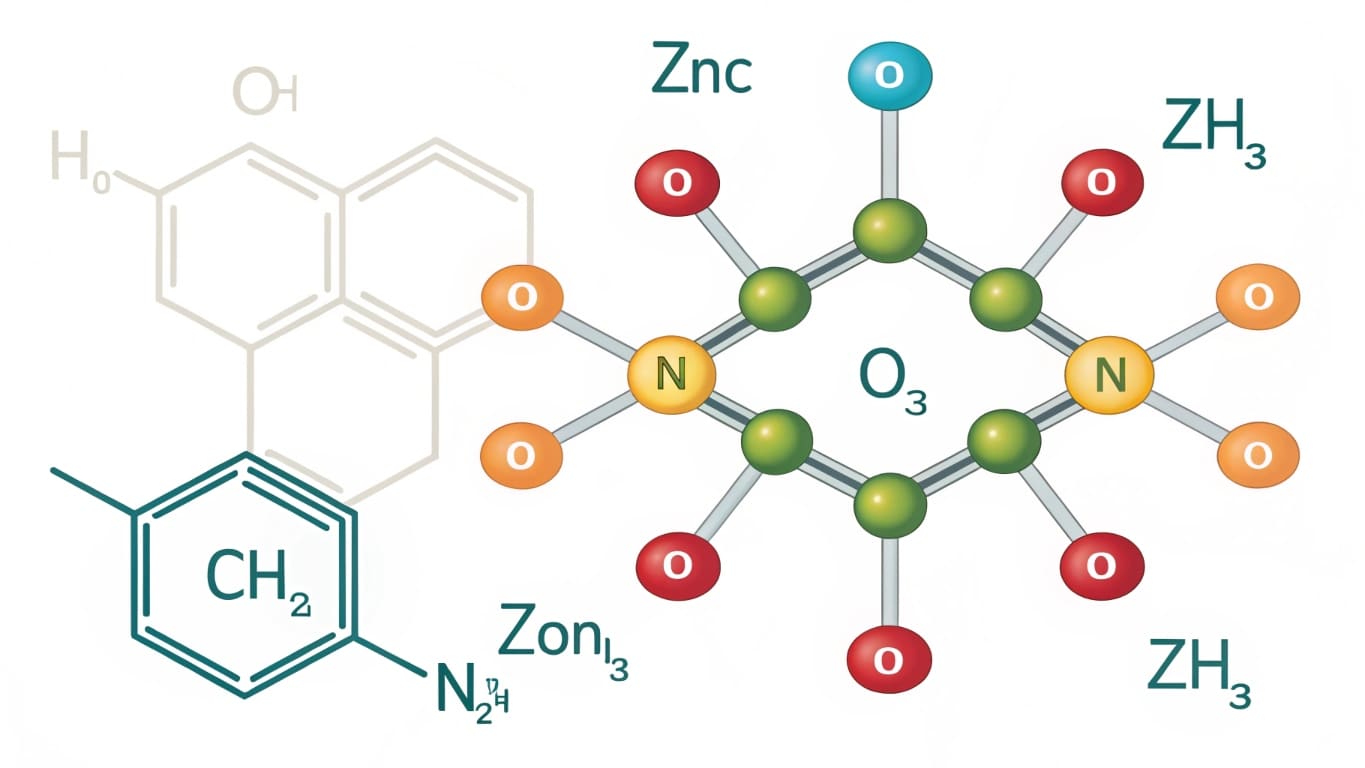

What is the chemical structure of accelerator ZDTP?

The chemical structure of ZDTP consists of a zinc ion coordinated with two alkyl dithiophosphate groups.

The molecular formula of ZDTP is Zn[O2P(S)(R)2]2, where R represents alkyl groups. The structure showcases a central zinc atom bonded to two dithiophosphate groups, each containing sulfur and oxygen atoms. This structure provides the compound with its unique properties, particularly its ability to act as an efficient rubber accelerator.

What is the use of ZDTP in rubber?

ZDTP is primarily used as a vulcanization accelerator in rubber production.

It promotes the crosslinking of polymer chains in rubber, which is essential for improving the rubber's mechanical strength and heat resistance. ZDTP is particularly effective in enhancing the durability and longevity of rubber products, such as tires and seals.

What kind of rubber accelerator does ZDTP belong to?

ZDTP is classified as a thiazole-type accelerator.

This group of accelerators is known for its effectiveness in promoting vulcanization reactions in rubber. ZDTP is often chosen for its fast activation, allowing for quicker processing times and enhanced vulcanization performance.

What are the key properties of ZDTP in terms of rubber performance?

ZDTP improves the elasticity, heat resistance, and aging properties of rubber.

Its primary function is to improve the crosslink density of rubber, which directly enhances its mechanical properties. The rubber becomes more flexible, durable, and resistant to wear and tear under various conditions, making it ideal for use in demanding applications like automotive tires.

Can ZDTP be used in latex applications, and what effect does it have on latex?

ZDTP can be used in latex applications, where it contributes to better crosslinking and stability.

In latex, ZDTP helps in stabilizing the polymer matrix, preventing premature aging and ensuring longer-lasting durability. It also improves the resilience and flexibility of latex products, making it suitable for items like latex gloves and foams.

How does ZDTP work in the vulcanization process?

ZDTP accelerates the vulcanization process by promoting the formation of crosslinks between polymer chains.

During vulcanization, ZDTP reacts with the sulfur present in the rubber, helping form sulfur-sulfur bonds between the polymer chains. This crosslinking increases the strength and elasticity of the rubber, ensuring better performance under stress and environmental exposure.

What are the applications of ZDTP in rubber manufacturing?

ZDTP is used in a wide range of rubber products, including tires, seals, and gaskets.

Its versatility makes it suitable for various types of rubber applications, especially those requiring high durability and resistance to heat and aging. ZDTP is also used in industrial rubber components, ensuring that these products perform efficiently over time.

What are the benefits of using ZDTP as a rubber accelerator?

The benefits of using ZDTP include enhanced rubber strength, flexibility, and longevity.

ZDTP accelerates the vulcanization process, which helps reduce manufacturing times and costs. It also improves the quality of rubber, making it more resistant to wear, aging, and high temperatures, thereby extending the lifespan of the final product.

Conclusion

ZDTP is a powerful rubber accelerator that enhances vulcanization, improves rubber performance, and offers a range of benefits for various rubber applications.