How to Select Rubber Accelerators And Antioxidants by Industry?

1. Introduction

Rubber accelerators and antioxidants play crucial roles in the rubber industry, ensuring that rubber products perform well during production and remain durable over time. Each of these additives serves a different purpose, but together, they help enhance the quality, efficiency, and longevity of rubber products.

Rubber Accelerators

Rubber accelerators are chemical agents used to speed up the vulcanization process, which is the process of crosslinking rubber molecules to improve elasticity, strength, and heat resistance. Accelerators reduce the curing time and energy required for vulcanization, thus increasing production efficiency and lowering costs.

Common rubber accelerators include:

- Vulcanization Accelerators: Such as ZDEC, ZDBC, TMTD, and MBTS, these accelerators are used in various rubber formulations to improve elasticity, wear resistance, and heat resistance of rubber products.

- Multi-functional Accelerators: Some accelerators also possess antioxidant properties, helping to prevent rubber degradation while facilitating vulcanization.

- Applications: Rubber accelerators are widely used in the production of tires, hoses, seals, footwear, and other rubber products. The choice of accelerator depends on the specific performance requirements of the product.

Rubber Antioxidants

Antioxidants are additives used to prevent rubber from oxidizing and deteriorating over time. Oxidation can cause rubber to harden, crack, and lose its mechanical properties, especially when exposed to heat, oxygen, and ozone. Antioxidants neutralize oxidants or inhibit oxidation reactions, thereby prolonging the life of rubber products.

Common antioxidants include:

- Wingstay L: A widely used antioxidant in various rubber products, particularly in tires and automotive components, where it helps prevent aging due to heat, oxygen, and ozone exposure.

- TMQ (2,2,4-Trimethyl-1,2-dihydroquinoline): An effective antioxidant, commonly used in the automotive industry, tires, and seals to prevent oxidative degradation and extend the product’s lifespan.

- IPPD (N-isopropyl-2-benzothiazole-1,1′-dimethylthiolamine): Another commonly used antioxidant, especially in tires, hoses, and other rubber products, where it enhances resistance to oxidation and aging.

- 6PPD (N-(1,3-dimethylbutyl)-N’-phenyl-p-phenylenediamine) is a commonly used antioxidant in the rubber industry, particularly in the production of tires. It is an effective additive that helps prevent oxidative degradation, which can lead to the breakdown of rubber compounds, loss of strength, and premature aging.

Summary

- Rubber Accelerators speed up the vulcanization process, improving the elasticity, durability, and heat resistance of rubber, making them indispensable in rubber manufacturing.

- Antioxidants help prevent rubber degradation by inhibiting oxidation, thereby increasing the longevity and performance of rubber products.

Together, rubber accelerators and antioxidants work in tandem to ensure that rubber products meet the necessary performance standards and maintain their quality throughout their lifespan.

Selection of rubber accelerators and rubber antioxidants in various industries

Rubber Accelerators and Antioxidants in the Tire Manufacturing Industry

Tires are one of the most significant applications in the rubber industry. Tire manufacturers face multiple challenges, including wear resistance, aging resistance, and cost control, making the selection of suitable accelerators and antioxidants crucial.

Wear Resistance and Aging Resistance: Tires operate in complex environments and must withstand road wear and various weather conditions. To ensure excellent wear and aging resistance, sulfenamide accelerators (e.g., CBS) and thiazole accelerators (e.g., MBTS) are widely used. Sulfenamide accelerators offer a longer induction period for more uniform vulcanization, increasing durability.

Antioxidant Selection: Commonly used tire antioxidants include 6PPD, which provides excellent protection against ozone and fatigue, suitable for natural and synthetic rubber. RD (TMQ) also offers protection against aging caused by heat and oxygen, a key component in radial tires. Microcrystalline wax can also form a protective layer to further enhance aging resistance.

Balanced Vulcanization: To ensure even vulcanization across the tread and carcass, accelerator combinations are often used. For example, TBBS with vulcanization activators balances vulcanization rates, improving safety and durability.

Environmental and Safety Considerations: With stricter environmental regulations, the tire industry increasingly uses low-aromatic oils and eco-friendly accelerators to replace high-toxicity options, reducing environmental impact.

Rubber Latex Glove Manufacturing Raw Materials

Rubber gloves are essential in daily life and medical applications, with strict requirements for safety and comfort, especially in accelerator selection.

Fast Vulcanization and Low Toxicity: Gloves, often made from natural rubber, require fast-vulcanizing accelerators like dithiocarbamate (e.g., ZDEC, ZDBC), thiazole(e.g., ZMBT) and thiurams (e.g., TMTD). As gloves come in direct contact with skin, low-toxicity or non-toxic accelerators are becoming industry trends.

Antioxidant Selection: To enhance glove durability, low-toxicity antioxidants (e.g., polyphenol antioxidants(WingStay L), bisphenol antioxidants(2246), or MB) are commonly used to prevent long-term aging.

Allergy Prevention: Some accelerators, such as MBT, may cause skin allergies. To reduce allergy risks, manufacturers increasingly use low-allergen accelerators or sulfur-free systems (e.g., peroxide curing) to minimize impact on sensitive users.

Latex Pillows&Matress Manufacturing

Rubber Accelerators

ZDEC (Zinc Diethyldithiocarbamate): an Ultra-fast vulcanisation accelerator for latex foaming processes, capable of initiating a fast vulcanisation reaction.

ZMBT (Zinc-2-mercaptobenzothiazole): with good ageing resistance, it is often used in latex products to improve the vulcanisation efficiency and prolong the product life.

DPG (diphenyl guanidine): guanidine accelerator, usually used for foam stabilisation to ensure the uniformity and quality of latex foam. But DPG has aniline, which will cause cancer in human beings. But we have a new eco-friendly material that could replace DPG and is not harmful to humans.

Antioxidant:

Wingstay L: is a general-purpose antioxidant that effectively prevents the ageing of latex products at high temperatures and in oxygen environments. It is particularly suitable for latex foam products (e.g. pillows and mattresses) and extends product life.

The combination of these accelerators and antioxidants helps to maintain foam stability during the production of latex pillows and mattresses and to improve the ageing resistance and service life of the products.

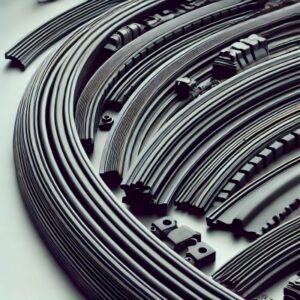

Cable and Wire Industry Requirements

The cable and wire industry has specific requirements for rubber materials, needing good electrical insulation and stability over prolonged use.

Heat Resistance and Insulation:

Thiazoles: including MBT (2-thiol-based benzothiazole), MBTS (disulfide dibenzothiazole) and so on. These accelerators play an important role in the rubber vulcanization process and can improve the vulcanization speed and vulcanization effect1.

Secondary sulfonamides: such as CBS (N-cyclohexyl-2-benzothiazole secondary sulfonamide), TBBS (N-tert-butyl-2-benzothiazole secondary sulfonamide), NOBS (N-oxo-linked diethylidene-2-benzothiazole secondary sulfonamide), and so on. These accelerators have better processing performance and vulcanization effect and are commonly used in the manufacture of wire and cable1.

Columnarium: including TMTD (tetramethyl disulfide columbium), TMTM (tetramethyl columbium monosulfide), TETD (tetraethyl columbium disulfide) and so on. These accelerators can significantly improve the vulcanization speed of rubber, and are suitable for the manufacture of wire and cable1.

Thiocarbamates: such as ZDEC (zinc diethyl dithiocarbamate), ZDBC (zinc dibutyl dithiocarbamate) and so on. These accelerators show good processing performance and vulcanization in rubber and are suitable for the manufacture of wire and cable1.

Guanidine: such as DPG (diphenyl guanidine), these accelerators show good processing performance and vulcanization effect in rubber, suitable for the manufacture of wire and cable 1.

The specific roles and application scenarios of these accelerators are as follows:

Thiazoles and hyposulfonamides accelerators: mainly used to improve the vulcanization speed and vulcanization effect, applicable to the manufacture of various rubber products, including wires and cables.

Thiuram and thiocarbonate accelerators: they can significantly improve the vulcanization speed of rubber, and are suitable for the manufacture of wires and cables that require fast vulcanization.

Guanidine accelerators: have good processing performance and vulcanization effect, are applicable to the production of wire and cable, and can provide stable vulcanization effect.

Antioxidant Selection:

Antioxidant MB

Antioxidant MB is a white or light yellow crystalline powder with a bitter taste, non-toxic. Its specific gravity is 1.42, melting point is 285℃, soluble in ethanol, acetone, ethyl acetate, insoluble in dichloromethane, insoluble in carbon tetrachloride, benzene and water. Antioxidant MB is suitable for wires, cables, shoe materials, etc. When the dosage is more than 2 parts, there will be frost phenomenon1.

Antioxidant TMQ

Antioxidant TMQ is resin-like, amber to off-white in color, and non-toxic. Its softening point is not less than 74℃, soluble in acetone, benzene, chloroform, carbon disulfide, slightly soluble in petroleum hydrocarbon, insoluble in water. Antioxidant TMQ is suitable for natural rubber and synthetic rubber such as styrene-butadiene, fixed eye, etc. The dosage is generally 0.5 to 3 parts. It has excellent protection against thermo-oxidative aging effect, and can passivate copper, iron, manganese and other heavy metal ions, but made of vulcanized rubber has an unpleasant odor 12.

Antioxidant IPPD

Antioxidant IPPD is applicable to antioxidant for wire and cable rubber, which can effectively prevent the performance degradation of wire and cable due to aging in the process of long-term use.

Footwear Industry Manufacturing

In footwear, the choice of accelerators and antioxidants directly impacts product performance and longevity.

Accelerators: Sulfenamide, thiazole, and thiuram accelerators are commonly used to expedite vulcanization and enhance production efficiency.

Antioxidants: Common antioxidants, like RD, 6PPD, and MB, help extend footwear life by preventing long-term aging and cracking.

Abrasion Resistance and Elasticity: Abrasion resistance directly impacts footwear lifespan, especially in the outsole. Thiazole (e.g., MBT) and dithiocarbamate (e.g., ZDC) accelerators are often used to enhance durability and elasticity.

Automotive Parts Manufacturing

Rubber Accelerators

Thiazoles: e.g. M (2-thiol-based benzothiazole) and DM (disulfide dibenzothiazole) 1.

Subsulfonamides: e.g. CBS (N-cyclohexyl-2-benzothiazole subsulfonamide), TBBS (N-tert-butyl-2-benzothiazole subsulfonamide), NOBS (N-oxo-linked diethylidene-2-benzothiazole subsulfonamide) and DZ (N,N’-dicyclohexyl-2-benzothiazole subsulfonamide) 1.

Columines: e.g. TMTD (tetramethyltetramethylene disulfide), TMTM (tetramethyltetramethylene monosulfide), TETD (tetraethylene tetramethylene disulfide) and DPTT (pentamethylene tetramethylene hexasulfide) 1.

Thiocarbamates: e.g. ZDC (zinc diethyldithiocarbamate), BZ (zinc dibutyldithiocarbamate) and PZ (zinc dimethyl dithiocarbamate)1.

Guanidine: e.g. D (diphenylguanidine)1.

Application and role of these rubber accelerators in automotive rubber parts:

These rubber accelerators are mainly used in automotive rubber parts to accelerate the vulcanization process and improve the physical properties and chemical stability of rubber. For example, hyposulfonamide accelerators improve the tensile strength and abrasion resistance of rubber, while thiuram and thiocarbonate accelerators improve the processing properties and vulcanization speed of rubber1.

Advantages and disadvantages of different accelerators:

Thiazoles: have a good promotion effect, but may be corrosive to equipment.

Hyposulfonamides: fast vulcanization speed, excellent product performance, but higher cost.

Thirams: fast vulcanization, but may produce harmful gases.

Thiocarbonates: fast vulcanization, but may affect the physical properties of rubber.

Guanidine: Accelerating effect is significant, but may affect the processing performance of rubber.

Antioxidant

Antioxidant BLE-W

Antioxidant BLE-W is a general-purpose rubber antioxidant for natural rubber, chloroprene, nitrile, butadiene, butylbenzene, paraben and other synthetic rubbers and latex. It has good protective properties against heat, oxygen, ozone, climate and flexing, etc. It is easy to disperse in the rubber material and is suitable for the production of tire treads, tapes, hoses and other industrial products12.

Antioxidant RD

Antioxidant RD (also known as TMQ) is a commonly used rubber antioxidant for rubber tires, conveyor belts, hoses and other products. It has good anti-aging properties and can extend the service life of rubber products3.

Antioxidant DTPD

Antioxidant DTPD is a new type of p-phenylenediamine antioxidant, characterized by small volatility, slow oxidation and long protective effect. It is suitable for heavy-duty, off-road and car tires under harsh conditions, and can effectively prevent ozone and flex-cracking4.

Usage and effect of antioxidants

These antioxidants are usually added in the production process of rubber products, and the dosage is generally 0.5 to 3 parts. They can significantly extend the service life of rubber products and improve their heat-, oxygen-, ozone-, and flex-cracking resistance. For example, the antioxidant BLE-W performs well in both natural and synthetic rubber, providing effective protection against the effects of heat, oxygen, ozone and climate.

Automotive Parts Manufacturing

In the production of waterproof rubber components, the selection of accelerators and antioxidants is crucial for ensuring the rubber’s performance, durability, and weather resistance. Here’s a detailed introduction to the commonly used accelerators and antioxidants for waterproof rubber components:

Accelerators

Accelerators are used to speed up the vulcanization process, improving the rubber’s physical properties. Common accelerators used in waterproof rubber components include:

Sulfenamide Accelerators (e.g., CBS, TBBS):

- CBS (N-Cyclohexyl-2-benzothiazole sulfonamide): CBS is known for its excellent overall performance, improving rubber’s heat stability, elasticity, strength, and weather resistance. It is widely used in waterproof rubber components, enhancing their resistance to high temperatures, moisture, and UV exposure.

- TBBS (N-Tertiarybutyl-2-benzothiazole sulfonamide): TBBS offers similar benefits to CBS, accelerating vulcanization and ensuring that rubber components are durable, flexible, and resistant to harsh outdoor conditions.

Thiazole Accelerators (e.g., MBT, MBTS):

- MBT (Mercaptobenzothiazole) and MBTS (Dibenzothiazole Disulfide): These accelerators are commonly used in general rubber products and provide cost-effective solutions for improving rubber’s wear resistance, water resistance, and chemical stability. They are widely used in waterproof rubber components, offering good processing characteristics.

Dithiocarbamate Accelerators (e.g., TMTM, DPTT):

- TMTM (Tetramethylthiuram Monosulfide): TMTM is known for improving high-temperature stability and crosslinking in rubber. It is particularly suitable for waterproof rubber components that require enhanced mechanical performance and heat resistance.

- DPTT (Dipentamethylenethiuram Tetrasulfide): DPTT accelerates vulcanization more effectively and is ideal for certain specialized applications where improved aging resistance and oxidation protection are required, making it suitable for waterproof rubber components.

Antioxidants

Antioxidants are used to prevent the rubber from aging, hardening, or cracking due to oxidation caused by heat, oxygen, ozone, and UV exposure. Common antioxidants used in waterproof rubber components include:

Antioxidant 4010NA:

- Antioxidant 4010NA is a widely used antioxidant in waterproof rubber components. It effectively slows down the aging process caused by oxidation, UV light, and ozone. It provides excellent heat and weather resistance, making it ideal for outdoor rubber products such as seals, roofing materials, and waterproof coatings.

Antioxidant MB:

- Antioxidant MB (N-Isopropyl-N’-phenyl-p-phenylenediamine) is another commonly used antioxidant in industrial rubber products. It prevents oxidation and aging, ensuring that rubber components retain their flexibility and resistance to cracking or hardening over time. It is particularly useful for waterproof rubber products exposed to high temperatures and humid environments.

Rubber Accelerators like CBS, TBBS, MBT, MBTS, TMTM, and DPTT accelerate the vulcanization process and improve the heat stability, flexibility, strength, and weather resistance of waterproof rubber components. They are essential for ensuring that the rubber maintains its performance in demanding outdoor conditions.

Rubber Antioxidants such as Rubber Antioxidant 4010NA and Antioxidat MB prevent oxidation, aging, and hardening of the rubber, ensuring long-lasting durability and flexibility for waterproof rubber components exposed to UV light, moisture, and extreme weather conditions.

By selecting the appropriate accelerators and antioxidants, manufacturers can produce waterproof rubber components that meet the long-term performance requirements for outdoor applications, ensuring they maintain their functionality and reliability over time.